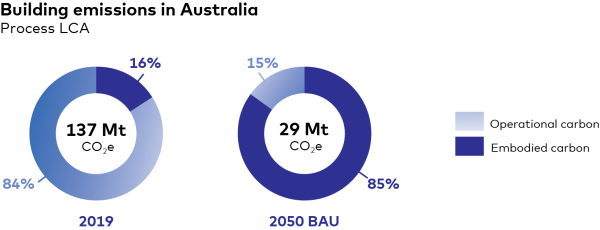

Without action, the share of Australia’s overall greenhouse gas emissions caused by embodied carbon in buildings could rise by over 50 percent between 2019 and 2050, finds a joint report by thinkstep-anz and the Green Building Council of Australia.

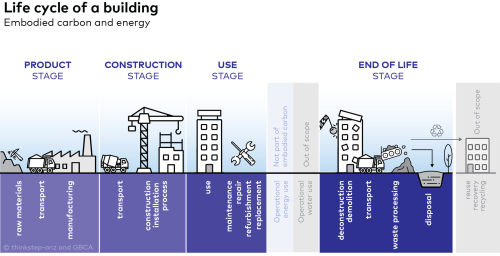

Embodied carbon versus operational carbon

The report Embodied Carbon & Embodied Energy in Australia’s Buildings highlights the increasing significance of embodied carbon and embodied energy in the building sector’s carbon footprint. The report compares the 2019 baseline year to a 2050 business-as-usual scenario to show what could happen without deliberate action on embodied emissions. Embodied carbon refers to the emissions ‘embodied’ in both the building materials and the processes required to create and demolish buildings.

The operational emissions from processes such as lighting and heating buildings will decrease over time as Australia’s electricity grid decarbonises to become 100% renewable by 2050. Further reductions in operational emissions will be achieved by replacing fossil fuelled sources of heating such as natural gas with renewable electricity-driven sources such as heat pumps.

Embodied carbon will replace operational carbon as the dominant source of building emissions as Australia’s electricity grid decarbonises.

Because embodied carbon is not directly linked to electricity use, it is less affected by changes in the electricity grid. As a result, embodied carbon will replace operational carbon as the dominant source of emissions from buildings by 2050. Without targeted and collaborative action, embodied emissions are forecast to form 85 percent of total carbon emissions of Australian buildings by 2050, from a baseline of 16 percent in 2019 (Figure 2).

Embodied carbon and energy in materials comes from five sources:

- Stationary combustion of fuels, typically for thermal energy (e.g. natural gas, LPG)

- Mobile combustion of fuel in vehicles (e.g. diesel, gasoline, LPG, CNG)

- Direct process emissions (embodied carbon only)

- Purchased energy, typically electricity

- Purchased goods and services — a result of the 4 sources above

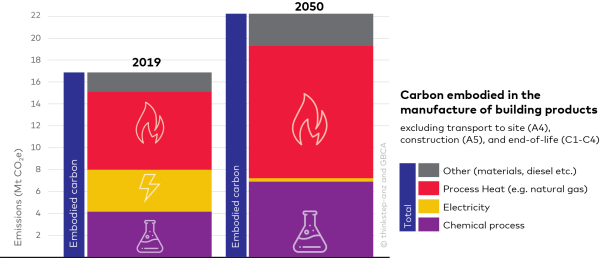

Figure 3 shows the carbon embodied in the manufacture of building products, split into the sources. The story this graph tells is that as electricity decarbonises, process heat (e.g. natural gas) and chemical process emissions (e.g. that coming from cement production) become more important. Finding ways to switch process heat generation from fossil fuels to using electric heating where possible or biofuels (wood, landfill gas, etc.) will greatly reduce the impacts of this sector.

Figure 3: Sources of embodied carbon emissions from the manufacture of building products used in construction and maintenance

Meeting Australia's net-zero goal requires a greater focus on embodied carbon.

For high-performance new buildings, research (R. Augros et al. 2019) has shown that embodied carbon contributes around 45 percent of the whole-life carbon emissions.

In 2018, the ‘Trajectory for Low Energy Buildings’ identified that buildings accounted for 18 percent of Australia’s greenhouse gas emissions. However, Australia’s national plan to build zero energy buildings, does not include embodied carbon — the emissions required to construct these buildings. Decarbonising buildings in line with state, national and international net-zero targets require more efforts directed at decarbonising the products and materials used in constructing buildings.

There are significant opportunities to reduce embodied carbon and embodied energy in Australia’s buildings.

Strategies to reduce embodied carbon and embodied energy can be broadly categorised into supply side and demand side. Supply-side strategies target the emissions sources identified in Figure 3 above (thermal energy, direct process emissions, electricity, and other). Demand-side strategies target which materials or products are selected, how much of each material is needed, and how construction and demolition waste is managed.

Importantly, both strategies are often complementary. If you manufacture a product with a lower impact per unit and you also need fewer units then you win twice.

Suppliers and customers both have important roles to play.

Supply-side strategies include working on:

- Energy efficiency and material efficiency projects

- Designing and supplying lightweight products

- Stopping process emissions from reaching the atmosphere (carbon capture and storage)

- Decarbonising electricity grids through increased use of renewables

- Substituting thermal energy (e.g., replacement of coal with natural gas, natural gas with biogas, or natural gas with biomass)

Demand-side strategies include working on:

- Designing to optimise material use and avoid waste generation

- Encouraging the use of rating tools like GBCA's Green Star, which specifically target reductions in upfront carbon emissions

- Substituting materials (i.e. substituting a higher-impact material for a lower-impact material that serves the same function)

- Designing buildings for multi-functionality so that fewer buildings are needed overall

- Prolonging the life of existing buildings through proper maintenance and renovation

- Recycling and upcycling of materials from decommissioned buildings

Decarbonising Australia’s building industry requires collaboration

thinkstep'anz's Technical Director Jeff Vickers sums up the main findings of the report in this short video.

There is an urgent need for additional policy incentives to decarbonise Australia’s energy supply, as well as investment in research and development of new materials and practices. Materials efficiency in the built environment plays an important role because emissions are saved immediately.

The carbon emissions from products and materials in buildings must be driven to net zero in line with the targets of the Paris Agreement, and State and Territory emissions reduction targets.

For a full list of reduction strategies, download our report below.

Report authors

thinkstep-anz: Jeff Vickers, Samuel Warmerdam, Steve Mitchell, and Nicole Sullivan

GBCA: Jorge Chapa, Sandra Qian