This month we get to the ‘pointy end’ of things. Using the concepts she explained in last month’s article, Nicky Andrews, our Head of Carbon, explains how to measure and reduce your carbon. But first, a recap.

Where we left off: identifying the main sources of your carbon emissions.

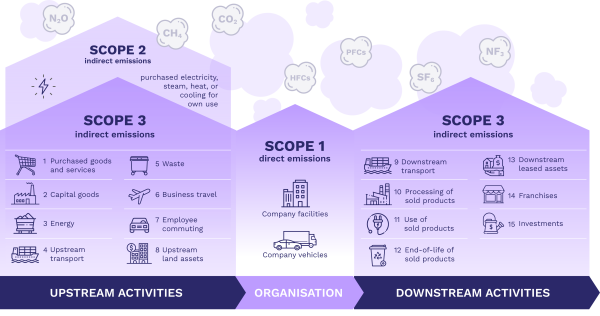

So you’ve taken the first step. You’ve split your greenhouse gas emissions into direct emissions (Scope 1), indirect emissions (Scope 2) and the hidden indirect emissions in your value chain (Scope 3). Now you’re ready to measure them.

Our thinkstep-anz diagram of carbon Scopes, based on International Greenhouse Gas Protocol

Step two: measure your emissions

Your Scope 1 and 2 activities

Measuring your Scope 1 and 2 emissions is relatively simple. You’ll need two pieces of data: the volume of emissions your activities create (‘your activities’) and the impact those emissions have on the environment (‘emission factors’).

First, confirm your activities. For example, how many kilometres did your employees drive in your company vehicles last year? How many kilowatt hours of electricity powered your plant? You’ll have much of this information on hand in documents like monthly fuel and power bills.

Second, find your emission factors. An emission factor represents the amount of GHG an activity releases. In Australia, the Department of Climate Change, Energy, the Environment and Water provide National Greenhouse Accounts (NGA) Factors. In New Zealand, the Ministry for the Environment (MfE) provides generic information factors, along with helpful workbooks and guides. For example, according to MfE, one litre of diesel used for transport emits 2.69kg of CO2 equivalent.

Third, do the maths. Units of activity x emission factor per unit = CO2e released.

Your Scope 3 emissions

These are the emissions in your value chain. They sit with your employees, suppliers and customers.

Here’s an example of measuring the carbon in your supply chain. Say you want to estimate the emissions in Scope 3 Category 4 (upstream transport). Ask your suppliers: How much fuel do you use each year to transport your products to my factory? If they can’t tell you, estimate it. Units of activity (distance travelled between supplier factory and your site) x emission factor per unit = CO2e released.

Now let’s look at an example for emissions involved after your product leaves your factory: Scope 3 Category 11 (using sold products). Say your product is a dishwasher. Ask yourself these questions: How many dishwashers have we sold this year? What’s our dishwasher’s typical lifespan? How much energy does one cycle use? How often would a customer use their dishwasher? Units of activity (kilowatt hours of electricity) x emission factor per unit = CO2e released over your products’ lifetimes.

Step three: plan how you’ll reduce your emissions

Reducing emissions is about thinking differently. What can you change? Here are some examples manufacturers should consider. Think about:

- The energy you use. Can you move your fleet from fossil fuels and go electric? Or increase the renewable energy that powers your plant? Manufacturer Essity Australasia is moving from natural gas to renewable geothermal steam at its Kawerau plant to dry its tissue.

- Your product’s design. Can you redesign your product to use less electricity? Fisher & Paykel has done this with its appliances.

- Your packaging. Can you reduce your packaging by packing your product differently? Redesign it to weigh less? Use more recycled material and make it easier for consumers to recycle too? For example, Coca-Cola New Zealand has changed its Sprite bottle from green to clear as clear plastic can be more readily recycled.

- The waste you and your product create. Can you reduce this? GIB® manufacturer Winstone Wallboards has cut back the waste it creates when it makes plasterboard. It is also helping customers produce less waste when they use GIB® plasterboard on building sites.

Nicky’s tips to make progress

- Set targets. Reducing emissions takes time. Confirm your baseline, set realistic annual targets and review your progress regularly.

- Work with your suppliers and customers. You can’t reduce your emissions on your own. Ask your suppliers to reduce the packaging on the raw materials they send you. Talk with wholesale customers about combining shipments to reduce your transport emissions.

- Boost your influence. Help your procurement and sales teams talk about your carbon footprint so your suppliers and customers can help you reduce it.

- Work with your industry association. You’ll go faster together. For example, an industry may be able to influence common suppliers to reduce their emissions. In addition, some industry groups such as the building industry are producing tools to help members tackle emissions.

- Build your skills. You may need help to measure and plan your reductions in year one. You’ll learn a lot! Then aim to do this work in-house after that.

Get started now!

Yes, changes take time and cost money, but the benefits are many. Get started now and set your manufacturing business up for a low-carbon future.

A version of this article was first published in the October 2023 issue of New Zealand Manufacturer.