Chances are you’re already talking about carbon – and climate change too. If not, you need to start!

But when you’re a busy manufacturer, getting to grips with carbon can be daunting, we know. So in this first of two articles, our Head of Carbon Nicky Andrews explains how to get started and keep making progress.

Understanding carbon emissions

Nicky Andrews, our Head of Carbon

What are carbon emissions?

‘Carbon emissions’ is shorthand for ‘greenhouse gas emissions’ (GHGs) – the gases that are trapping heat in Earth’s atmosphere and warming our planet.

There are many types of GHGs. Common ones include carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O).

Why do manufacturers need to reduce carbon emissions?

You’ll be helping to keep global warming to below 1.5°C and meeting the goals of the Paris Agreement. There are many good business reasons, too, for manufacturers to tackle carbon.

How does my business benefit from reducing emissions?

First up, you’ll reduce your risks. For example, if the government introduces a carbon tax, you’ll be prepared.

You’ll strengthen your brand. Customers may already be asking what you’re doing to reduce your emissions. That’s because they (and their customers) are increasingly seeking lower-carbon products.

You’ll strengthen relationships. For example, you’ll keep your investors happy if you manage your emissions (and their money) carefully. Your team will value your efforts too. Many people want to work for a business that takes climate action seriously.

Finally, because winkling out carbon involves delving into everything you do, you’ll spot opportunities to reduce your costs.

What are the three Scopes (types) of emissions?

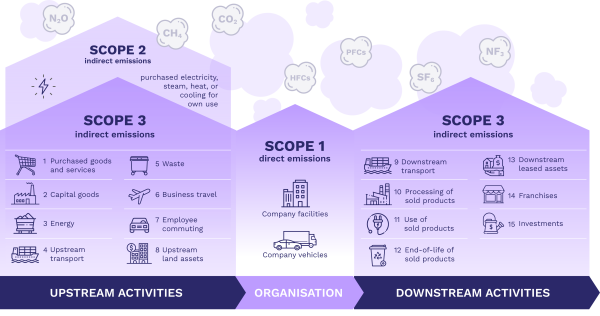

The international Greenhouse Gas Protocol is one of the standards that govern how organisations measure and reduce their carbon emissions. The Protocol splits carbon into three groups (Scopes).

Our thinkstep-anz diagram of carbon Scopes, based on International Greenhouse Gas Protocol

Scope 1 emissions are direct emissions. They come from day-to-day activities like fuelling your vehicle fleet with diesel.

Scope 2 emissions are indirect emissions. They come from the electricity you purchase to run your factory and the heat, steam and cooling you buy.

Scope 3 emissions are also indirect emissions. They may be your biggest group of emissions but they’re ‘hidden’ in your value chain. (These are the processes that add value to your business, like funding your operations and designing, producing, transporting, and marketing your product.) There are 15 categories of Scope 3 emissions.

How do we measure carbon emitted?

Some gases warm the earth’s atmosphere more than others. To keep things simple, we measure the impact of different GHGs as equivalents of carbon dioxide (CO2e). For example, methane is 28 times more powerful than carbon dioxide at warming the atmosphere so 1kg of methane equates to 28kg CO2e.

Reduce your carbon emissions in three steps

There are three steps involved: identify your main sources of emissions; measure your emissions; reduce them. This article explains the first step.

Step one: identify your main sources of emissions

Scopes 1 and 2

Look at the main activities that generate these emissions. Your Scope 1 GHGs may come from fuelling your vehicles with petrol and diesel, powering your factory with natural gas, and cooling your operations with refrigerants. Your Scope 2 emissions are likely to come from running your operations on electricity.

Scope 3

Start by ‘screening’ your emissions to find the sources of carbon that are most relevant to your business and most material in size. Our free thinkstep-anz Scope 3 Explorer will help you.

These sources are relevant to most manufacturers. Category 1 (purchased goods and services) covers the carbon in your raw materials. Category 4 (upstream transport) and Category 9 (downstream transport) account, respectively, for the carbon involved in transporting raw materials to your factory and delivering products to your customers.

Category 12 (end-of-life of sold products) measures the carbon your product emits at the end of its life. While every product has an ‘end of life’, this category is more important for some products than others. For example, paper, wood and food emit carbon in landfill. Plastic is relatively inert.

Some categories are relevant for some manufacturers only. Category 10 (processing sold products) is important if you manufacture an intermediary product like plastic resin. Your customers generate carbon when they make their own products from the resin.

Category 11 (using sold products) comes into play if your customers draw energy to use your product. For example, if you manufacture toasters, your customers use electricity to brown their morning toast. The design of your product influences how much electricity they use.

The nature of your product determines which categories matter most to your business. To gauge the size of your GHGs, you’ll need to consider (among other things) what your product is, what it is made of and how customers use and dispose of it.

That’s the theory lesson done. Next month we look at the practice: how to measure your carbon emissions and how to reduce them.

A version of this article was first published in the September 2023 issue of New Zealand Manufacturer.