Quantifying Circular Economy with the Materials Circularity Indicator

Many producers today are eager to make the transition from linear to circular models. However, doubts remain over how well a product’s materials align with circular economy principles of minimal waste and enhanced reuse value. Fortunately, the Materials Circularity Indicator is here to help.

Going circular

The circular economy is a system that requires us to reconsider the entire lifecycle of our products and resources by designing out waste. That means making use of materials and technologies that extend the lifespans and potential reuse value of the things we produce, while minimising unintended waste and pollutants as far as possible.

With that, there remains a need to quantify this progress so producers can know just how circular their products are. The Material Circularity Indicator (MCI) not only provides a benchmark for improving a product but can add extra value to an Environmental Product Declaration (EPD), providing a more accurate picture of the overall sustainability credentials of that product.

Measuring sustainability

Numerous rating tools and certifications exist worldwide to assess the sustainability credentials of a product or project and reward them accordingly. Looking at such properties as the GHG emissions and energy usage, these ratings give manufacturers a basis to work with and improve upon, whereas users can make the most informed choice during the initial design process.

EPDs and carbon product certifications both go a long way towards establishing a product’s overall environmental impact. Both look at the entire lifecycle of a product, are internationally standardised, and independently verified. However, they stop short of quantifying a circular economy approach. This is where the Material Circularity Indicator can help to offer a fuller picture and ensure that circular economy steps are well underway.

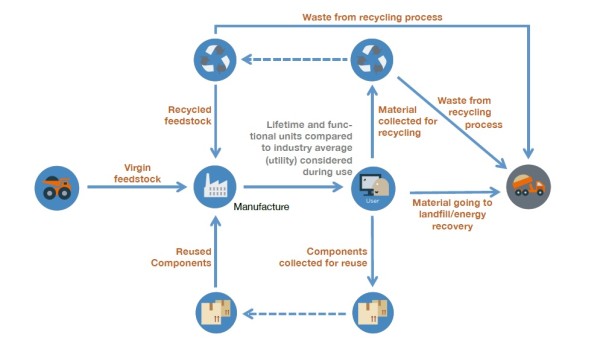

Figure 1: Diagrammatic Representation of Material Flows (Ellen MacArthur Foundation 2015)

The Material Circularity Indicator

The Ellen MacArthur Foundation, building on their strong work publicising the circular economy, developed the MCI to measure the circularity of products. The indicator’s focus is on Technical Cycles, “in which products, components and materials are kept in the market at the highest possible quality and for as long as possible, through repair and maintenance, reuse, refurbishment, remanufacture, and ultimately recycling.” (Ellen MacArthur Foundation 2015) With this, the MCI is particularly relevant to organisations working in building and infrastructure areas and encourages more circular design principles from the extraction of raw resources, to the construction and eventual demolition stages.

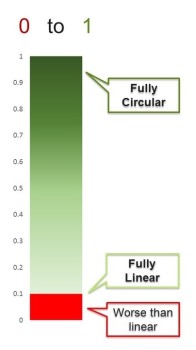

This process is demonstrated in figure 1, with the MCI tracking material flows from virgin stock, to use and eventual reuse. In short, its focus is entirely on the materials going in and the waste coming out along each step of a product’s lifecycle. It also considers a product’s utility when making the calculation, which includes the intensity of use and intended lifespan. Finally, the MCI has a simple scale of 0—1, with 0.1 indicating a linear process, and 1 indicating a fully circular one. A result of less than 0.1 indicates a linear product with lower than average utility.

What this looks like in practice

Following on from EPD work already carried out on a range of their products, InfraBuild (formerly Liberty Steel) commissioned thinkstep-anz to carry out an MCI on their reinforcing bar product. With a score of 0.669, the company found that they had a reasonably good benchmark but could also start to seek opportunities for improvement. Looking through their supply chain and manufacturing process, InfraBuild could identify the material contributions of their Electric Arc Furnace which is fed primarily by recycled scrap metal, and their blast furnace facility, both of which contribute towards the production of their reinforcing bars. With the MCI in mind, a decision could then be made to increase the usage of materials from their electric arc furnace which had a more positive overall contribution to their MCI.

Following on from EPD work already carried out on a range of their products, InfraBuild (formerly Liberty Steel) commissioned thinkstep-anz to carry out an MCI on their reinforcing bar product. With a score of 0.669, the company found that they had a reasonably good benchmark but could also start to seek opportunities for improvement. Looking through their supply chain and manufacturing process, InfraBuild could identify the material contributions of their Electric Arc Furnace which is fed primarily by recycled scrap metal, and their blast furnace facility, both of which contribute towards the production of their reinforcing bars. With the MCI in mind, a decision could then be made to increase the usage of materials from their electric arc furnace which had a more positive overall contribution to their MCI.

Additionally, with the MCI calculated on their reinforcing bar product, InfraBuild can look to incorporate it into the EPD. Indeed, InfraBuild and thinkstep-anz are building the MCI into all their EPDs in order to provide a more comprehensive indication of their products’ sustainability credentials.

In a broader sense, and in line with the objectives of the MCI according to the Ellen MacArthur Foundation, this MCI provides InfraBuild with an important piece to add to their growing sustainability puzzle. Although this MCI only applies to one of many products, it is nonetheless vital information as they shift from a linear production model to a circular one. In the future it could help to assess the MCI of larger, more multifaceted projects, of which the reinforcing bars are only one part.

Concluding points:

The material circularity indicator is an extremely useful tool for measuring and improving the circularity of a product. It can help to provide a more comprehensive picture when identifying hotspots in the production process, carrying out or evaluating an EPD, or assessing how a product fits into a project’s overall environmental impact.

Some final considerations to keep in mind when assessing how and when to utilise an MCI:

- MCI is only one piece of the puzzle and is less useful as a tool to use on its own. It should be considered alongside other indicators, such as those included in an EPD, to avoid burden shifting.

- For most products, MCI has many levels of detailed information and calculations at different levels. It shares most data requirements with those used for developing a life cycle assessment, making it a logical inclusion in LCA and EPD projects.

- The MCI distinguishes between reused and recycled materials; however, it does not separate different types of recycling, with ‘downcycling’ rated the same as closed-loop recycling. Future versions could improve on this in order to reward processes that maintain maximum material value.

- MCI will become increasingly relevant as circularity is measured in more products, enabling comparison between similar products as well as providing a benchmark for improvement.

By Barbara Nebel, CEO of thinkstep-anz

This article was first published in NZ Manufacturer magazine, May 2020.