The building and construction industry is facing a massive challenge to achieve climate change targets. One of the best ways for companies to influence change is through their spending. But where to start if you work with thousands of suppliers? New Zealand construction company Fletcher Building used spend-based emission factors to cut their supply chain emissions into 48,000 bite-sized pieces. This revealed the hotspots where they can most effectively drive change across the sector.

In 2019, Fletcher Building set verified science-based targets (SBT). This means their targets are in line with what climate science deems necessary to meet the goals of the 2015 Paris Agreement. Science-based targets show companies how much and how quickly they need to reduce their greenhouse gas emissions to prevent the worst effects of climate change.

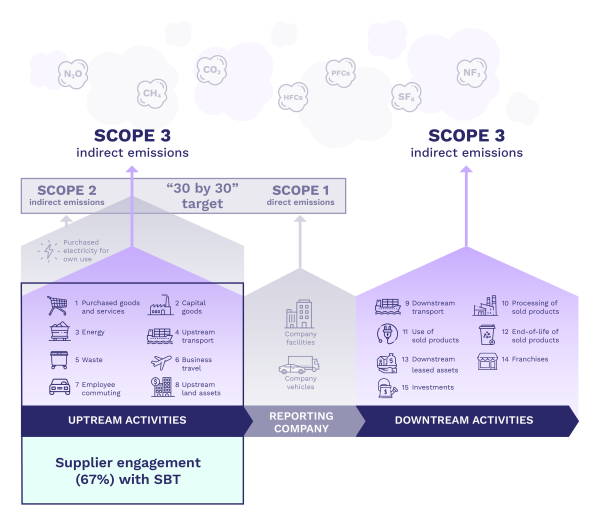

For the industry giant, these targets included reducing their emissions – combined direct (Scope 1) and indirect (Scope 2) – by 30 percent by 2030 from a financial year 2018 base year. Fletcher Building also committed to reporting on their emissions across the company’s entire value chain (Scope 3), and that 67 percent of their suppliers (by emissions) would have science-based targets themselves by 2024.

Fletcher Building's emission scope categories

How to estimate Scope 3 supplier emissions

The greenhouse gas protocol allows businesses to estimate their supplier emissions using:

- Primary, supplier-specific data sources including Environmental Product Declarations (EPDs) or site-specific emissions data.

- Secondary, estimated data sources including industry-average emission factors per material consumed, or per dollar spent, from emission factor databases.

- The Hybrid Method employing a mixture of primary and secondary data.

Where do you start with emission factors?

In the 2021 financial year Fletcher Building worked with 48,000 suppliers. Far too many to individually engage with, estimate or measure. To get a better idea about their supplier emissions, Fletcher Building used the spend method.

To do this, the top 1,000 suppliers by spend are split into categories including waste, machinery, residential building construction, and heavy and civil engineering construction. The dollars spent in each category are then multiplied with category-specific emission factors – the expected emissions from a supplier per dollar spent (measured in kilograms of carbon dioxide equivalent per dollar (kg CO2e/$)).

Using an input-output Life Cycle Assessment (LCA) database, Fletcher Building calculated the average emission factors from these suppliers and applied them to their remaining suppliers to get a good idea of their total supply chain emissions.

Previously Fletcher Building used the DEFRA (UK) factor set as it was the only readily available database. The application of this data for the New Zealand market was however limited as these emission factors were developed for the UK market and not updated after 2011.

thinkstep-anz has released a white paper Emission Factors for New Zealand. This report provides greenhouse gas (carbon footprint) emissions factors for goods and services purchased in New Zealand. We used Input-Output Life Cycle Assessment (IO-LCA) to calculate the values at the national level. This method estimates the environmental emissions resulting from a wide range from activities in our economy.

Dr Michael Burgess, Group Carbon & Environmental Performance Manager at Fletcher Building, says thinkstep-anz’s emission factors significantly decrease the error for New Zealand-based spend data and most categories are easily mapped from DEFRA.

Estimating supplier emissions with the spend method, Fletcher Building found that the top 67% of their supply chain emissions came from 180 vendors, with the top 10 vendors accounting for 40% of total emissions.

Using data to drive supply chain engagement

With a much more manageable number of suppliers to tackle, Fletcher Building went to work. They now knew the percentage of their Scope 3 emissions covered by suppliers with an existing science-based target. The business also knew how many of their top suppliers have an incentive to set their target. This was either because they are members of the Climate Leaders Coalition and have pledged to do so, or because they have to adhere to upcoming mandatory climate-related disclosure requirements. Last year the New Zealand government passed legislation making climate-related disclosures mandatory for large publicly listed companies and organisations in the financial and insurance sector.

‘More importantly, we now know which businesses to engage with more closely,’ Burgess adds. ‘We can approach them and share our journey – and encourage them on their journey.’

‘While this method doesn’t give us a perfect picture of what our supply chain emissions look like,’ Burgess says, ‘it gives us a really good look at them.’ The key value for Fletcher Building was identifying suppliers the business needs to engage with and working alongside them to create a more sustainable building and construction industry.

Apart from talking with individual suppliers, Fletcher Building is also engaging with others through the Carbon Disclosure Project’s Supply Chain programme. The international programme helps members to engage with their suppliers, pinpoint risks and identify opportunities.

thinkstep-anz’s whitepaper Emission Factors for New Zealand

The report Emission Factors for New Zealand – Greenhouse Gas Emission Intensities for Commodities and Industries is available now and

- includes all direct and indirect carbon emissions in New Zealand

- includes the carbon embodied in international trade

- lists separate emissions into Scope 1, Scope 2 and Scope 3 categories (wherever possible)

- records greenhouse gases separately, allowing multiple IPCC carbon footprinting methods to be used