What are EPDs and why are they so important in the building and construction industry? We talked in a webinar to Andrew Eagles, CEO of the New Zealand Green Building Council (NZGBC) about upcoming changes to mandatory embodied carbon reporting for building projects and increasing carbon requirements for Homestar ratings.

The built environment is responsible for about 20 percent of Aotearoa New Zealand’s overall carbon emissions. Achieving net zero greenhouse gas emissions by 2050 will require transformative change. We need to massively reduce the carbon footprint of our housing stock to stay within the international climate target of 1.5°C warming by 2050. In 2019, the NZGBC commissioned thinkstep-anz to investigate the hidden emissions and untapped potential of buildings for New Zealand’s 2050 zero carbon goal. ’The study "Under Construction" set out to look at the total impact of embodied carbon emissions and the potential to reduce that,’ NZGBC Chief Executive Andrew Eagles explains.

Spotlight on ‘hidden emissions’

Embodied carbon emissions stem from the materials and products a building is made from and can occur right across the building’s life cycle. The most significant embodied carbon emissions happen typically before a building is used, in producing construction materials and products.

’We looked at how materials like concrete, aluminium and steel could reduce their carbon impacts,’ Andrew says. ’We found there was potential to reduce CO2 emissions by over 1,200,000 tonnes by 2050, which is equivalent to taking 460,000 cars off New Zealand’s roads.’

How EPDs can help the industry to cut down on carbon

An Environmental Product Declaration (EPD) is one of the most reliable ways to know how carbon-intensive materials are. An EPD is a certified, independently verified assessment of the environmental impact of a product and is widely recognised by industry and governments. It looks at a material’s entire product life cycle from the raw materials, through manufacturing, to constructing, to end of life or recycling.

As EPDs are based on international standards, information from one material is comparable with those of another material. They can also be put together to get the full information about the impact of an entire building. Globally there are now over 10,000 EPDs of building materials. More than 100 businesses in Australasia already have an EPD and more are joining the growing list every week.

Change is coming

New Zealand’s Ministry of Business, Innovation and Employment (MBIE) has set out its plans to introduce mandatory disclosure of embodied carbon for new buildings from 2024/25, followed by a phased introduction of carbon emissions caps for new buildings.

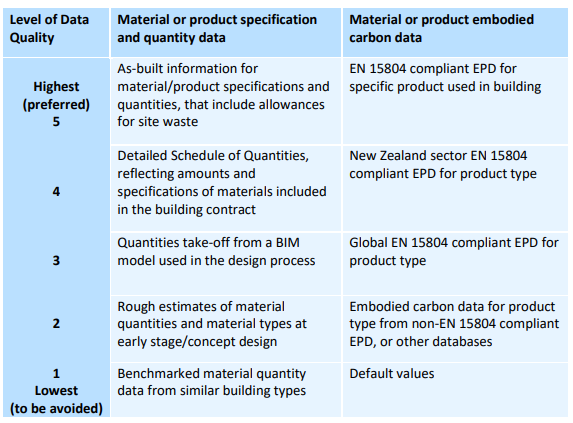

In its whole-of-life embodied carbon emissions reduction framework MBIE, recognises EPDs as the highest level of data quality. The second highest level of data quality is a sector-level EPD for an industry association. These do not look into a specific product but can be a good way for an industry to get started.

Clear information for designers and specifiers

EPDs will help designers and specifiers understand the carbon footprint of the products they use in their designs and tenders and meet the new MBIE rules.

Clear incentive for material providers

While EPDs are not mandatory for material providers, there is a clear incentive to get one. Carbon calculators will most likely advantage products with an EPD because they can provide accurate data. Products without an EPD will fall under ‘average data’, which is regarded as lower quality, and awarded lower scores. Carbon calculators will likely assign these products a footprint larger than the carbon they actually emit. This will make them a less attractive choice for progressively carbon-conscious designs.

‘When you need to get consents for a new building or a new home, you will be asked to input your embodied carbon calculations for your building,’ Andrew explains. ’When you have an EPD, you have good data and you can be solid in your response, but when you have products that use default data, many carbon calculators will use very conservative data, and your project will be disadvantaged in the process,’ he adds.

Greater focus on embodied carbon for Homestar

There has been a sharp increase in uptake of the NZGBC’s Homestar certifications, with more than 5,000 registrations in the last six months alone. Homestar is an independent rating tool for assessing the health, efficiency, and sustainability of homes across Aotearoa. The new Homestar version 5, which is available now, requires embodied carbon calculations at 8 Homestar rating or above. Embodied carbon information will soon be required to receive a 6 Homestar or above certification. EPDs will be key to getting accurate data.

Developed by GBCNZ with support from thinkstep-anz, the Green Star Design and As Built 1.1 tool will launch in late April. It assesses the sustainability outcomes from the design and construction of new buildings or major refurbishments across nine holistic impact categories.

The updated tool will involve calculating embodied carbon and includes minimum performance thresholds for embodied carbon that will ratchet up over time. It also rewards Life Cycle Assessment with credits. This is another example of how EPDs will support ‘green’ credentials.

As the urgency to mitigate the impacts of climate change increases, EPDs give designers, specifiers, building code officials, and prospective house owners solid information so they can be sure they’re on the right track to decarbonising the built environment.